Pivot into Space programme to the fore at major aerospace event

The achievements of eight innovative projects that are pivoting Midlands manufacturers into the high-growth space industry as part of a £1m R&D programme were recognised at Farnborough Airshow, the largest tradeshow of its kind in the world this year.

Pivot into Space companies with the UK Space Agnecy and MAA teams at the UKSA pavilion

The Pivot into Space programme, which is being led by the Midlands Aerospace Alliance with funding from the UK Space Agency – matched by industry – has already created a launchpad into the space industry for nine small supply chain companies of a size that would normally face significant barriers to entering this demanding sector. The programme has not only provided grant funding worth £18,000 - £50,000 to each company, but also valuable technical and commercial guidance, access to industry contacts, exclusive events, and networking opportunities.

The fast-track programme means that, following a rigorous assessment process by technology experts, the companies selected for the programme will have transformed their existing capabilities and technologies into potential solutions for space industry challenges within 12-18 months. These solutions will then have a wide range of applications in the UK’s growing space markets including use on spacecraft, launchers and ground support equipment. Even though the projects are only part-way through, so great is the potential that several have already attracted customer interest, with some customers already actively guiding and supporting them.

Now, as the global industry gathers for the largest industry event of the year, three of the Pivot into Space companies have taken to the stage at a dedicated technology conference at Farnborough Airshow to share their initial results. Burcas, PAK Engineering, and SHD Composites each presented cases studies showing how they have been transforming their specialist knowledge and skills to provide solutions to technology challenges faced by the space sector.

Farnborough Airshow has proved the perfect opportunity to recognise the progress of these innovative projects as they enter their advanced stages. With 74,000 visitors expected to visit throughout the week, it was an optimum opportunity for these companies to showcase how their innovative capabilities can potentially transform the space sector.

Antonia Yendell, Head of Space Ecosystem at the UK Space Agency, said:

“Pivot Into Space is one of a number of initiatives that support the UK’s regional Space Clusters to build further on their strengths – in this case, the Midlands Space Cluster’s rich heritage in engineering and innovation. By backing innovative companies across the Midlands to unlock new opportunities and access growing markets, we want to kickstart economic growth, enhance our space capabilities and strengthen our national space ecosystem.”

“We’ve been really excited by how many small Midlands manufacturers have come forward with novel ideas to help the space industry solve a range of technical problems,” said Andrew Mair, Chief Executive, Midlands Aerospace Alliance. “The Midlands is a rich pool of engineering talent keen to diversify into the high-growth markets of the future. With great support from the UK Space Agency, Pivot into Space is fast becoming a trailblazing programme that is helping our companies build on what they’re good at to create new business opportunities in new markets.”

Brandauer creates precision stamped components for space motors

High-speed precision stamped component manufacturer, Brandauer, knew that its capabilities in stator and rotor laminations could give a technological advantage for space motors and wanted to pursue this. The company’s project has set about pivoting the ability to stamp ultra-thin electrical steels, improving motor efficiency, and enabling weight and mass reduction. Work carried out to remove the need for secondary stamping lubrication, and therefore the associated trace materials, reduces the risks of vacuum outgassing in a space environment. In parallel, Brandauer is developing infra-red and in-die glue bonding technology, to improve tensile sheer strength, temperature management and thermal resistance.

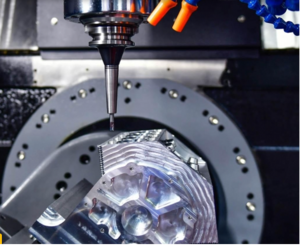

Burcas manufactures precision propulsion components for hypersonic speeds

Precision machining company, Burcas, is developing the manufacturing technology required to produce precision cryogenic turbopump components which will run at hypersonic speeds. These turbopumps have been designed by LENA Space and are already set to be used on a launcher for a European Space Agency programme. Longer-term, this will also lead to a state-of-the-art solution that is suitable for the Taiwan Space Agency’s next-generation Satellite Launch Vehicle, and has wider potential for other global space programmes too.

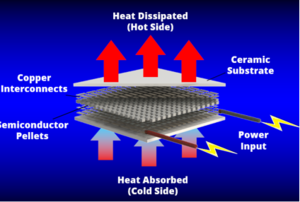

European Thermodynamics builds high-integrity SpaceTEC thermal devices

European Thermodynamics is dedicated to the design and supply of thermal management products. Its SpaceTEC project is focused on the development, construction and testing of a multi-stage Thermo-Electric Cooler (TEC) device designed to meet the demanding requirements of space instruments. It will make use of the company’s in-house produced semiconductor materials which have demonstrated superior performance. The European Space Agency has now awarded the company a contract for a new, single-stage TEC for use in space.

Geospatial Ventures steps into upstream space to enhance infrastructure monitoring

Geospatial systems integration and expert consultancy, Geospatial Venture’s project is enabling the company to step into constellation design and CubeSats – a class of microsatellites that typically perform monitoring activities in low orbit. The company is defining a Low Earth Orbit constellation of small CubeSats to transmit data from space to a device that will result in more accurate monitoring of ageing bridges and other structures, helping to improve security, safety and quality with minimal environmental impact. By the end of the project, they will have delivered a ‘FlatSat’ prototype.

Novocomms’ technology expands into Positioning, Navigation and Timing systems

Antenna technology company, Novocomms, will be building on their existing capabilities to develop a proof-of-concept demonstrator for a new Positioning, Navigation and Timing (PNT) system in response to the UK government’s ambition to strengthen the national infrastructure as PNT signals become increasingly important to daily lives. Novocomms’ dual antenna solution will be compatible with Low Earth Orbit satellites and will be specifically designed for ground-based mobile terminals to support remote areas. The company has support from a UK-based space industry customer whose modem will be integrated into the prototype.

PAK Engineering strives to improve the reliability of battery packs in space

PAK Engineering, an engineering solution provider, will be using its thermal management and advanced manufacturing know-how to improve the reliability of battery packs on CubeSats, working with the University of Nottingham on an existing platform. The heat exchanger will be 3D-printed with multiple materials to achieve optimised functional properties throughout the unit’s geometry such as optimal thermal transfer internally as well as toughness and heat resistance externally. This will be essential for the needs of rechargeable batteries on spacecraft, which are powered by solar panels in short bursts, as they must not degrade while operating in extreme space conditions.

DRVN Advanced Engineering and SHD develop sustainable composites for space

The mission to develop a flexible and scalable architecture for producing sustainable, flame-retardant composite panels for space structures has been undertaken as a partnership between two supply chain companies: DRVN Advanced Engineering – an engineering consultancy and composite manufacturing company – and SHD Composites – a developer and manufacturer of advanced, composite prepreg materials and technologies. The sustainable prepreg composite panels they are developing and testing will use natural fibre reinforcement and bio-resins which have the equivalent performance of carbon fabrics at a comparable cost.

Texture Jet develops a cleaner, faster and better way to get composites into space

Texture Jet designs and manufactures machine tools and will be taking its patented ArcSlice® technology into the space industry. The technology delivers scalable surface processing of non-conductive materials which is more efficient and increases sustainability in both production and service. The method enables adhesive or coatings applied to the surface to form a more secure bond than traditionally achievable. The project is an important development for the future of composite materials for space applications. It will enable a cleaner, faster and more cost-effective way to prepare composites for bonding and coating.