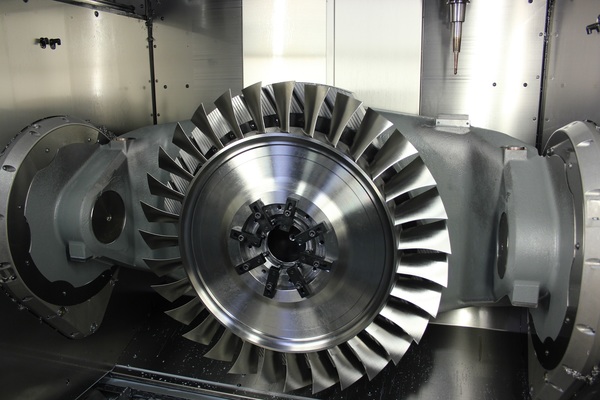

The new method covers the machining of the blisk from start to finish and combines new tooling concepts.

The new method covers the machining of the blisk from start to finish and combines new tooling concepts from Technicut with advanced machining strategies in Delcam’s PowerMILL software for the rough, semi-finish and finish machining of integrally bladed rotors.

A video of the new process can be seen on the Delcam AMS channel on YouTube at https://www.youtube.com/watch?v=W1nqbQHV1Ew. In this example, the cycle time was reduced to 35 hours, less than half the time that would have been needed using conventional methods, while the costs for milling were reduced by 45%. The initial billet was 804 mm diameter Ti6-4 titanium, while the completed blisk had 31 blades, each 84mm in length with a root radius of 4mm and scallop height of 10µm.

Click here for more information.