New technology developed with the help of the MAA's Aerospace Technology Exploitation Programme (ATEP) is already entering the aerospace supply chain. The great success of the 11 ATEP technology projects for aerospace supply chain companies -- coupled with the unique way ATEP was designed as a programme to fit the aerospace industry's requirements -- led the UK government to launch a national version, NATEP, to support 100 new projects between 2013 and 2017.

Aerospace Technology Exploitation Programme 1

The first phase of ATEP was launched in 2006 with grants to small consortia of companies funded by regional development agency Advantage West Midlands averaging about £80,000 plus expert help from the Midlands Aerospace Alliance.

Five projects were supported in this programme and produced results with wide-ranging benefits for aircraft programmes of the future, demonstrating the benefits of teaming SMEs and mid-sized companies with research bodies and end-users in highly focused problem solving -- combined with expert MAA guidance throughout the projects.

Aerospace Technology Exploitation Programme 2

The MAA ran this programme between 2009 and 2012 to encourage the development and exploitation of new technologies by companies operating in West Midlands' aerospace supply chains.

ATEP 2 was part-funded by the regional development agency Advantage West Midlands and the European Regional Development Fund, and helped larger manufacturers and SMEs work in partnership, sometimes involving leading universities and research organisations to develop new technologies that address emerging market requirements for future aircraft programmes.

Altogether, six projects accessed an average of about £120,000 of grant funding, plus expert MAA support, under the programme.

The ATEP projects

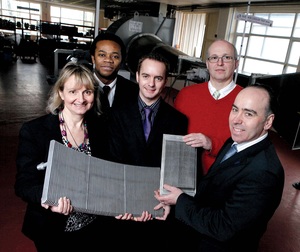

Innovative heat transfer systemBirmingham and Coventry's Meggitt Control Systems worked with the University of Birmingham and two local SMEs – Solihull's Arden Precision and PAB Coventry – to perfect a heat transfer system that improves heat exchanger efficiency. The technology involves a novel nickel-based metal foam (Retimet) and has proved to be a more effective heat transfer medium in a range of environments inside and outside aerospace. Info: nisar.ahmed@meggitt.com |

|

|

Nano-coatings for toolingTeer Coatings of Redditch and Anopol Ltd of Birmingham linked up to improve the life of tools for forging with nano-coatings technology, working with end-user Rolls-Royce. Info:kevin.cooke@miba.com |

Composites in actuation systemsWolverhampton-based Goodrich Actuation Systems worked with local SME Rojac and Advanced Composites Group to develop an actuator gear box housing in composite materials to replace traditional aluminium die-casting. The component is 60 per cent lighter. Following rigorous successful tests by Goodrich, the technology was inserted into the Airbus-led Next Generation Composites Wing Programme. Info: steve.sproson@utas.utc.com |

|

|

Low-cost bondingThe University of Wolverhampton, Ajax Toco and Unipart worked with HS Marston on a lower-capital-equipment-cost process with wide applications for aerospace and other manufacturers and led to a patent and further funding from other sources. Info: f.r.hall@wlv.ac.uk |

New alloys in heat exchangersWolverhampton-based HS Marston Aerospace worked with Telford SME Advanced Chemical Etchings to develop high temperature heat exchangers for aircraft engines made from new alloys. The new alloy heat exchanger can operate at up to 300ºC hotter than existing units. Info: david.scott@hsmarston.co.uk |

|

|

Novel materials for springsSMEs G&O Springs, Alloy Wire and Reliable Spring Manufacturing worked with the Institute of Spring Technology (IST), Aero Engine Controls and BAE Systems to characterise springs in novel materials such as titanium and various nickel alloys. Data enable accurate fatigue predictions for springs for the first time. Info: steve.boyd@springs.aero |

New design methods for tyresDunlop Aircraft Tyres developed new Finite Element Modelling techniques with the University of Birmingham. Airbus, the customer, regularly provided input to validate the models on existing and new tyres. Info: martin.pye@dunlopatl.co.uk |

|

|

Ceramics in aircraft brakesMeggitt Aircraft Braking Systems worked with SME James Kent Ceramic Materials, technology experts CERAM and customers Embraer and BAE Systems to investigate new ways to extend the life of aircraft brakes. Info: toby.hutton@meggitt.com |

Coatings without hazardous elementsIndestructible Paint worked with fellow SMEs Ashton & Moore and Clean Burner Systems, technologists at CERAM and customers Messier-Dowty and Rolls-Royce to remove chrome from engine-surface coatings. Info: brian@indestructible.co.uk |

|

|

Using surfaces as coolersHS Marston, with SME Advanced Chemical Etching and the University of Wolverhampton, modelled novel surface coolers and validated the models on a new test rig. Info: alanr@ace-uk.net |

Manufacturing novel aluminium alloyThe Aeromet-led project with SME partner Grainger & Worrall, the University of Birmingham, materials provider London & Scandinavian Metals and customer Aero Engine Controls developed manufacturing processes for a novel high-strength aluminium alloy, A20X. Info: alan.dustan@aeromet.co.uk |

|

For more information

The MAA team has developed a technology and capabilities roadmapping tool to help members undertake these important aspects of business strategy and planning. Please contact us for further information.

|

|